Starting with Energy Saving Motors

Reducing CO2 Emissions with Brushless Motors

By adopting an energy-saving motor for speed adjustment such as transportation, stirring, and winding, it is possible to reduce power consumption and CO 2 emissions. The brushless motor is a speed control motor that combines a compact, high-efficiency motor with a hall sensor and a dedicated circuit (driver) that performs feedback control.

The Effects of Using a Brushless Motor

Annual power consumption (compared with output 60W)

| Power consumption (kWh / year) |

CO 2 emissions (kg / year) |

Electricity charge (SGD / year) |

|

|---|---|---|---|

| AC motor | 439.2 | 228 | 123 |

| Brushless Motor | 273.6 | 142 | 77 |

● Daily drive time 12h, annual operating days 300 days, power -CO 2 emission conversion coefficient 0.519kg-CO 2 / kWh, power tariff 0.28 cents / kWh

●The usage conditions are as follows; AC motor: output 60W , Single-phase 200V, 60HZ brushless motor: BMU series, output 60W

Reduction of power consumption: 165 kWh/year

CO2 emssions: 86 kg/year, 37% reduction

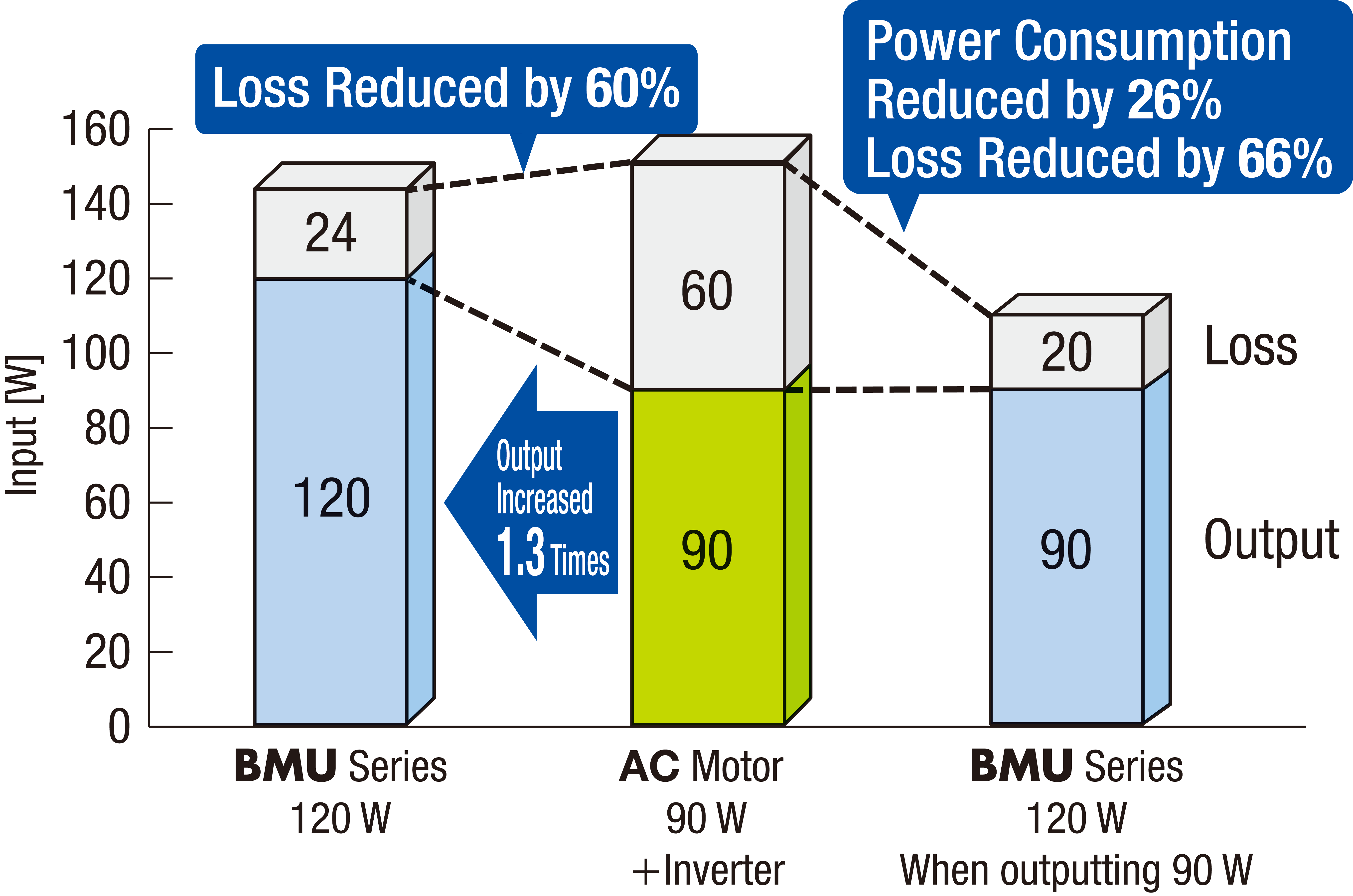

More Efficient than Inverter Control

Brushless motors use permanent magnets in the rotor, suppressing rotor secondary loss. This results in a roughly 26% reduction in power consumption compared to a three-phase induction motor for inverter control*. This helps the equipment to save energy.

* When Output Power is 90 W

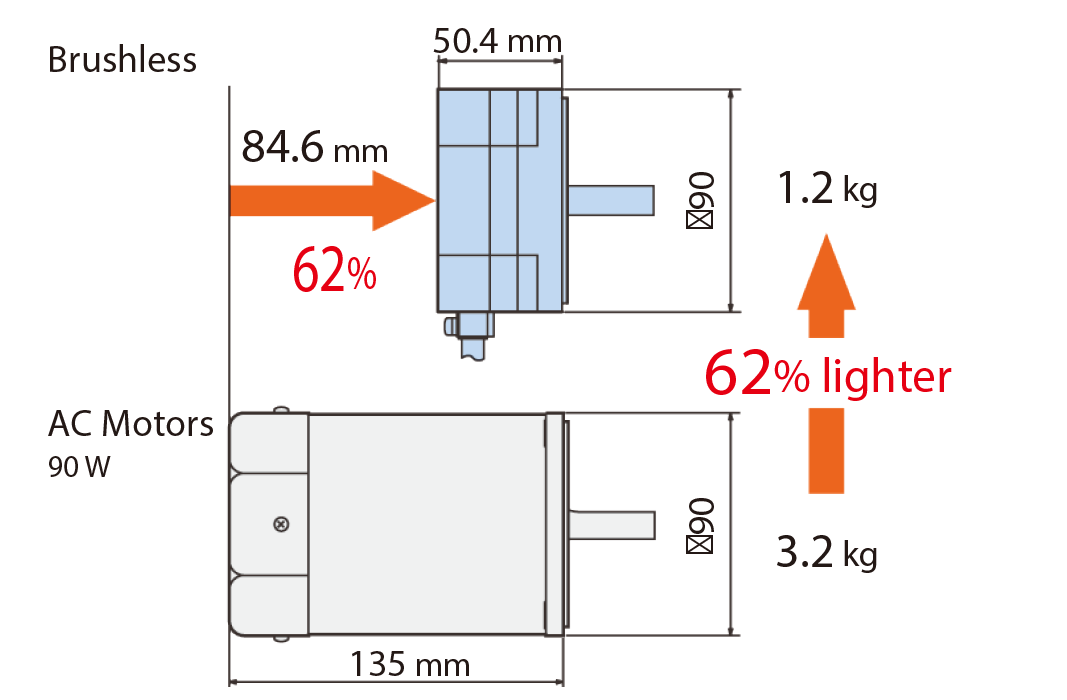

A Smaller, Lighter Motor Means Fewer Natural Resources

Brushless motors with built-in permanent magnets are both slim and high-power. For example, compared to a three-phase induction motor of frame size 90 mm, their total length is 84.6 mm shorter. This contributes to equipment downsizing and the use of fewer natural resources.

Compatible Products

A huge variety of motors is available, from ones that offer easy speed adjustment with a dial to ones that offer position control and network control. Select the motor that best suits the application at hand.

Energy Saving Motors Control Cabinet New equipment design Product Use Choosing the Optimal Products